iNisys (inline NVH inspection system)

Inline NVH Quality Inspection System

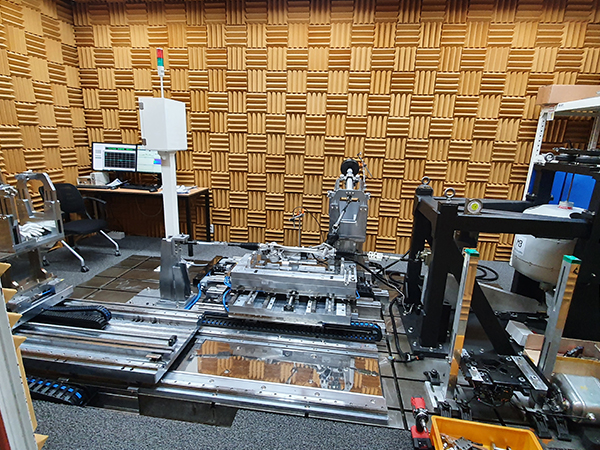

iNisys (iNisys – inline NVH inspection system) is an application for vibration analysis of rotating bodies based on Frequency Analysis and Order Analysis. It is useful for inspection of shock vibration signals of engines, motors, etc., and noise and vibration quality inspection of drivelines such as transmissions, motors, reducers, rear axles, front axles, hydraulic pumps, torque converters, and torque transfers.

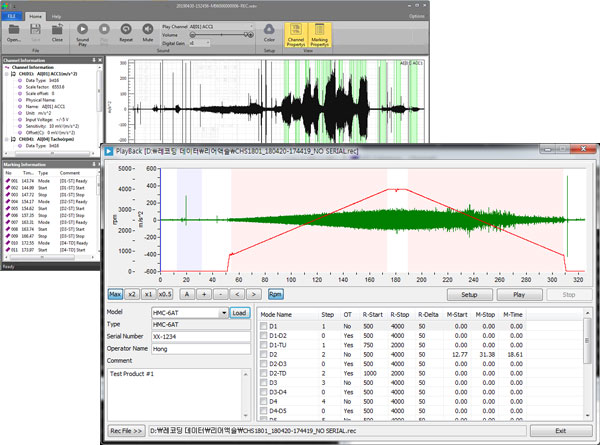

iNisys can perform time domain analysis such as Rms, Peak, Crest Factor, and Kurtosis, and frequency domain analysis such as Harmonic, Sideband, Harmonic Sum, and Curve. Also, order tracking curve analysis for rotation speed is possible. An external control communication protocol and database related application are provided for inline inspection.

In addition, when our Neurobox inspection engine is used together, it is possible to detect the type of impact fault signal that general frequency analyzers and order analyzers cannot detect.

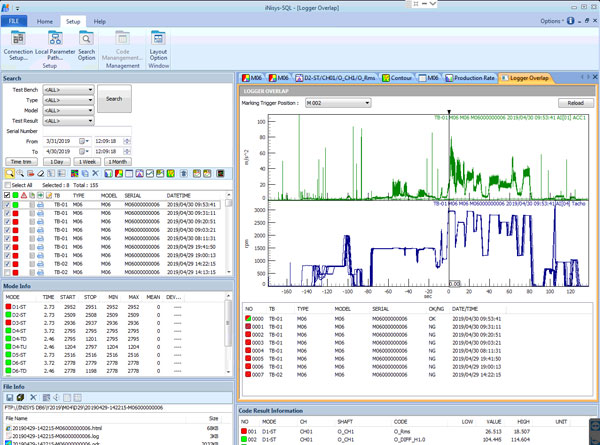

Recently, the post-processing analysis function was strengthened in iNisys to reproduce the situation measured in EOL and to check the presence or absence of specific issues during measurement. In addition, it has been implemented so that the user can hear it by outputting it again as sound. And by adding functions such as Logger Overlap, the analysis function has been strengthened.

Hardware Specification

4CH DSA

8CH DSA

Sensor Module

| Items | Specifications |

|---|---|

| A/D | 24-bit / 102.4kHz |

| Channels | 4ch or 8ch for Analysis (Acceleration or Microphone) / 1ch for Indexing |

| Order Resolution | 0.125, 0.25, 0.5, 1.0 selectable |

| Max Order | 1024, 512, 256, 128, 64, 32 |

| Speed Range | Up to 12000rpm (Max = 256 Order) |

| Input Signal Range | ±10V (Dynamic Range : Min 100dB) |

| Stethoscope | Speaker, Headphone (option) |

| Sensor | Accelerometer(Sensor Module), Microphone (option) |

Software Specification

NVH Measurement Application

- Time Signal / Spectrum Graph Display

- Drive & Driven Shaft separation function

- Defect Position Display

- Order Tracking Measurements

- Color Map Measurement (STFT, Spectrogram)

- Communication Logging and Display

- Device Check function

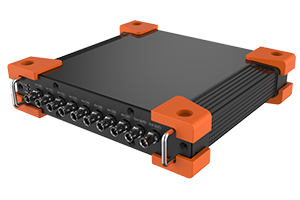

Parameter Management Program

- Rotating body specification input (number of gear teeth/motor pole, etc.)

- Test type management

- Measurement mode and code management

- Batch function

- Line code management Standard value status Check

- MES code and DPID status Check

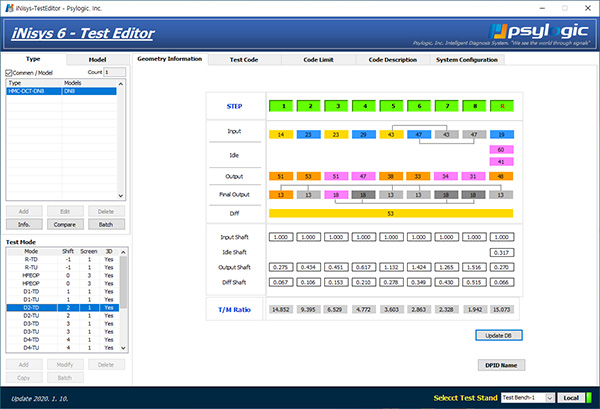

Data Search/View Program

- Order Tracking Overlap

- Spectrum Overlap

- Trend View

- Report Format setting and output

- First Pass Yield (Direct pass rate) check function

- post-processing learning

- Statistical processing first (mean, standard deviation, NG rate)

Wave Recording & Playback

- Full Cycle Recording and Sound Output function

- Save Test mode and measurement time information

- Wave File Analysis Tool

- Recording data rolling (automatic deletion of 1 month archive) function added

- Head Acoustics HDF file output

- Compare vehicle evaluation and EOL evaluation data in one DB (Database)

- International standard data format conversion - LMS, B&K readable

Analog Logger Overlap function

- Vibration Rms trend for full cycle can be viewed or data overlap of multiple products is possible

- Measurement and overlap of physical quantities such as Torque, Force, Pressure, and Rpm are possible

Application

- Motor & Drive Unit

- TransAxle & Transmission

- Power Transfer Unit

- Engine

- Transmission Parts

- Engine Parts

- ETC.

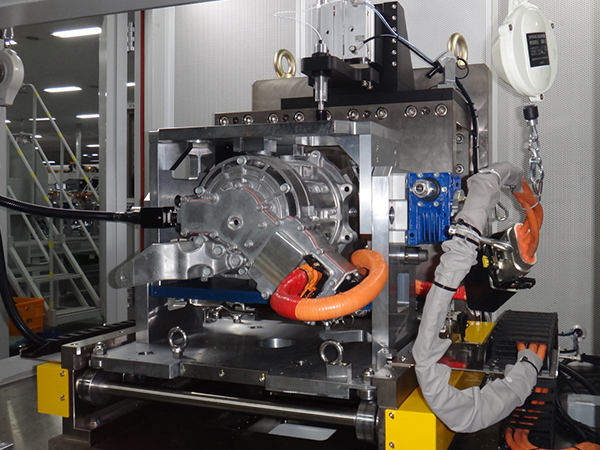

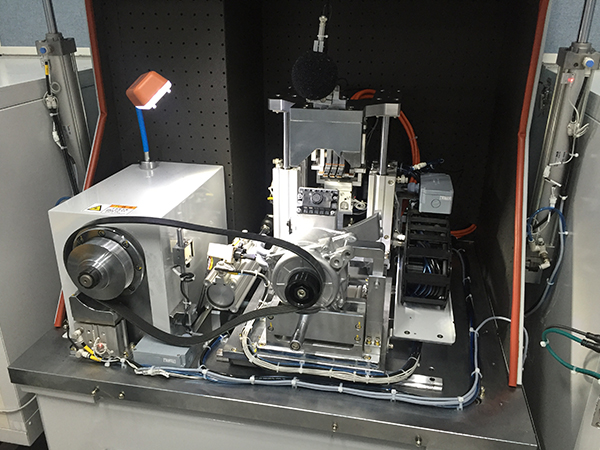

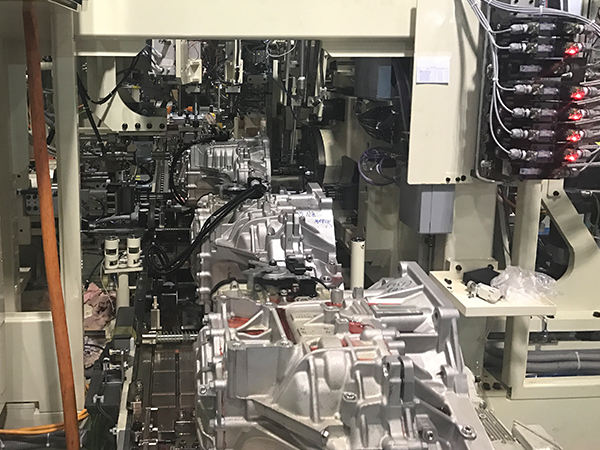

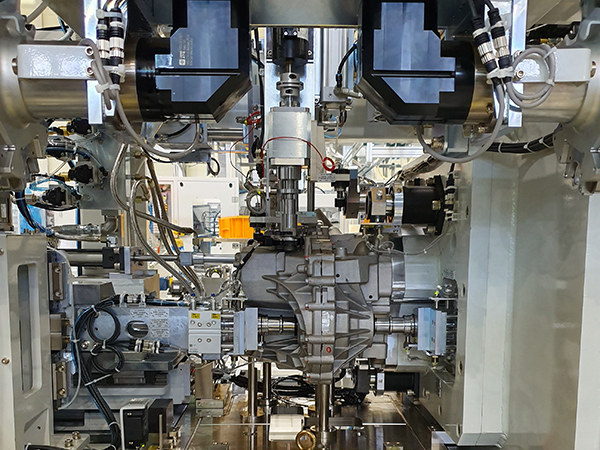

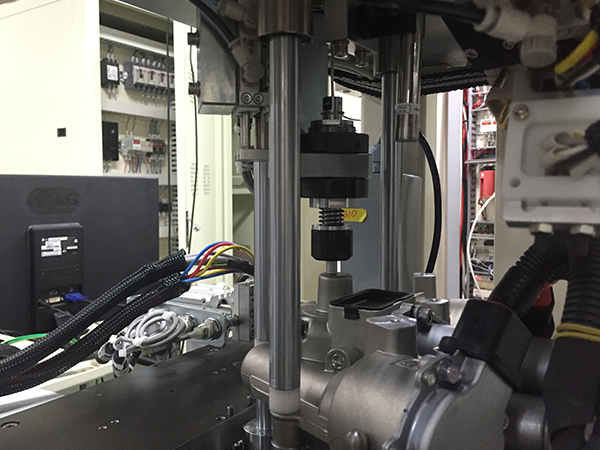

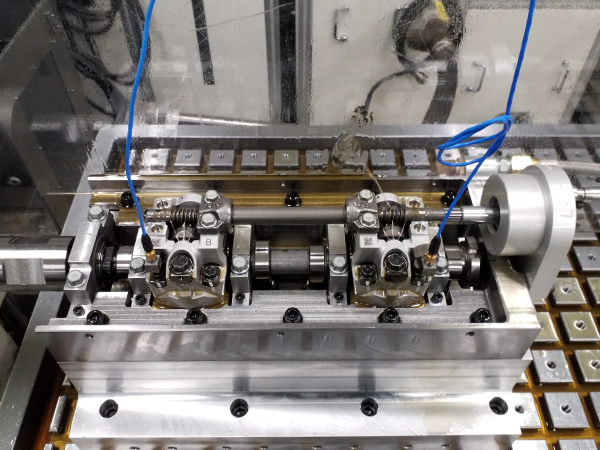

Drive unit production/assembly lines have increased rapidly due to the recent demand for electric and hybrid vehicles.

iNisys is capable of vibration inspection of motors and drive units that require high-speed order analysis over 6000~12000 RPM.

▲ EV Motor

▲ HEV Motor

▲ Drive Unit

▲ Electric Compressor

▲ HSG

▲ Start Motor

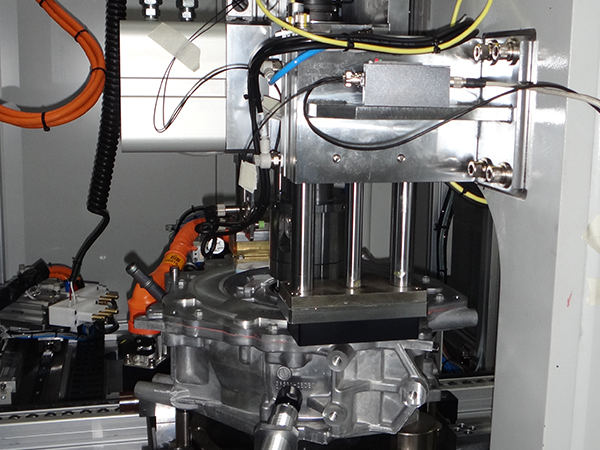

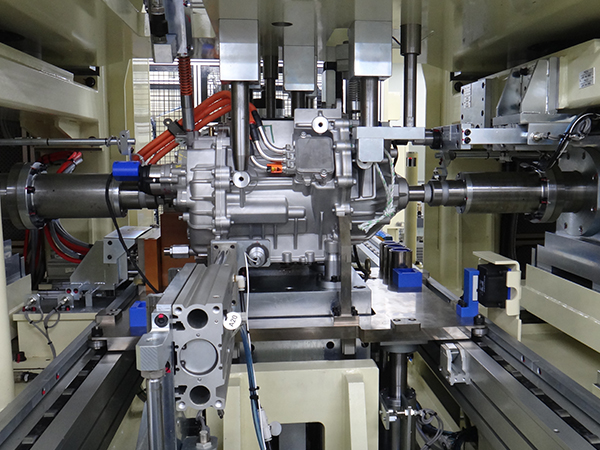

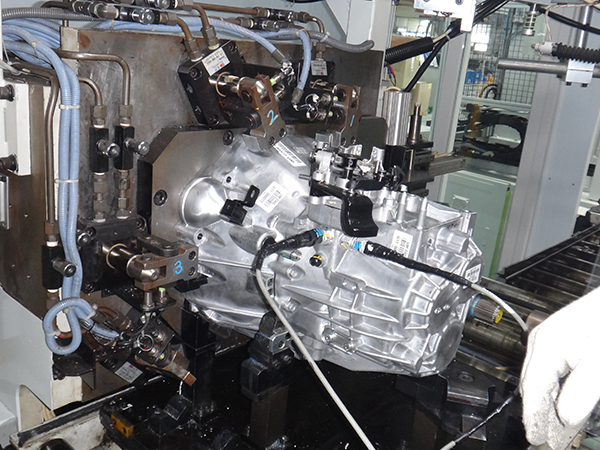

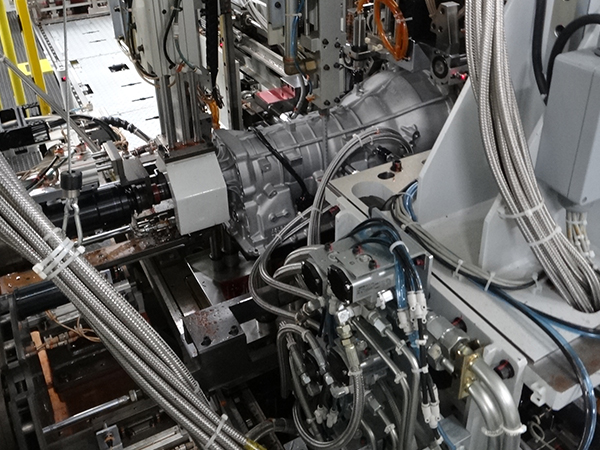

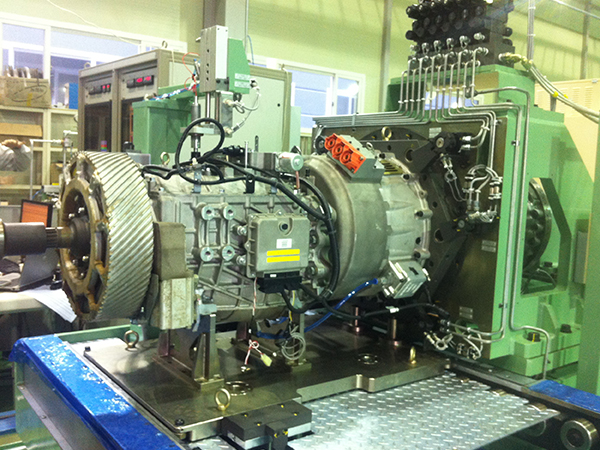

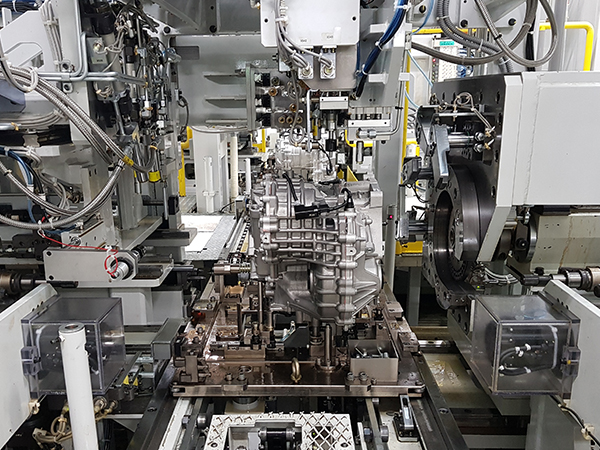

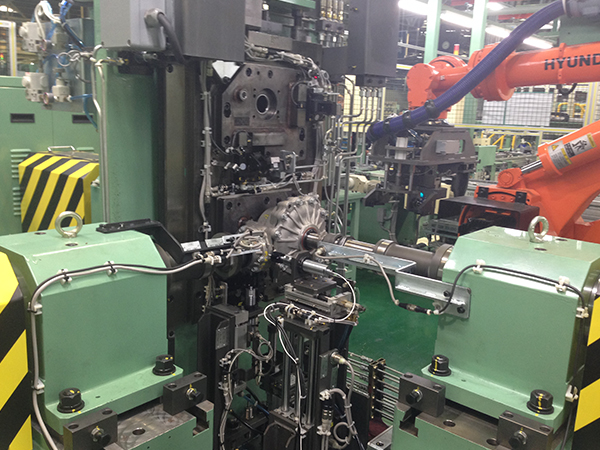

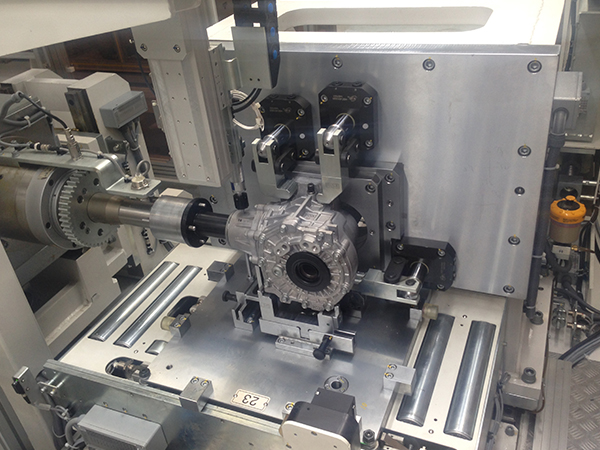

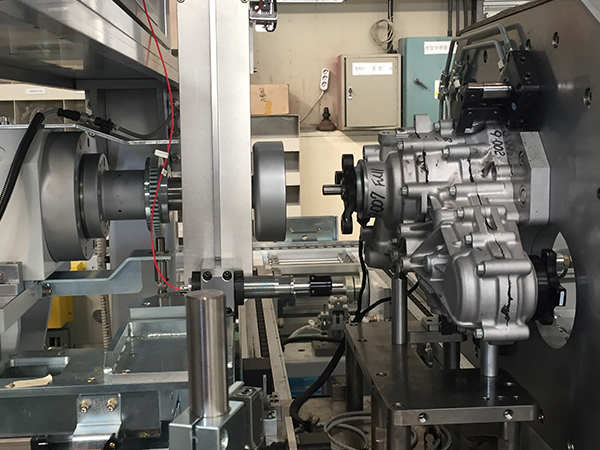

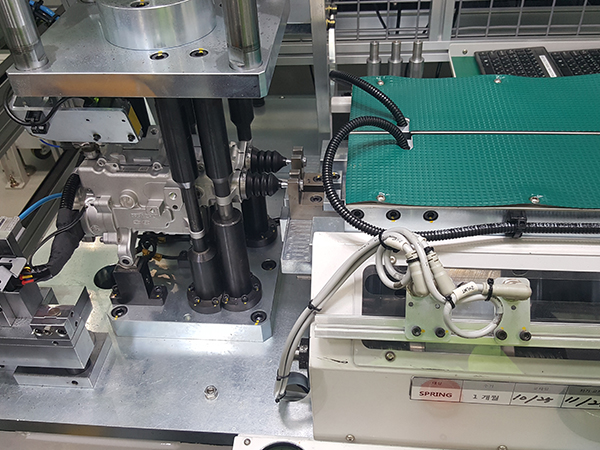

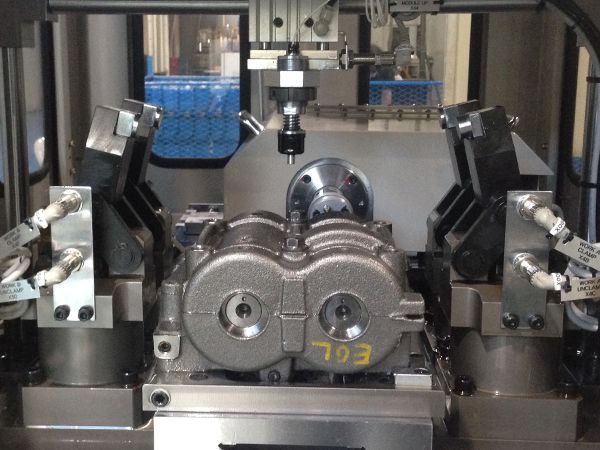

Psylogic has a record of selling hundreds of transmission inline inspection systems and has the appropriate know-how. Inspection of defective parts of the transmission is performed through order analysis and drive/driven shaft separation technique, and it can be applied to structures such as planetary gears and CVTs. (Automatic calculation of Belt or Chain order)

▲ M/T

▲ 6AT

▲ FR8AT

▲ AMT

▲ DCT

▲ CVT

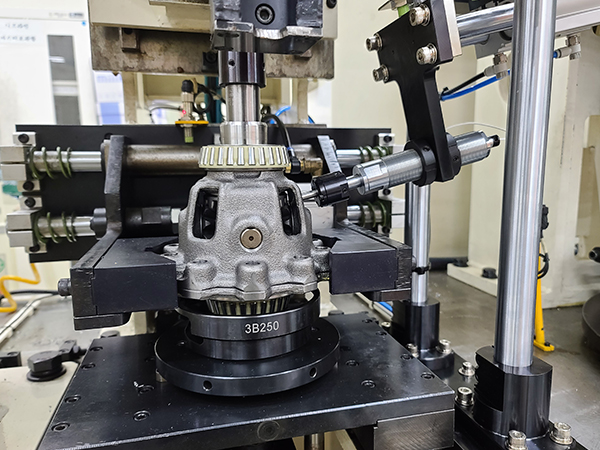

Among the power transmission devices, Axle, PTU, ATC, etc. have a simpler structure than the transmission, but problems arise in NVH repeatability and multiple test Benches value deviation depends on assembly condition of input & output motor on Test Benches. Psylogic diagnosis the root causes of Test benches through NVH Data.

▲ Front, Rear Axle

▲ PTU

▲ 상용 Axle

▲ ATC

▲ Torque Transfer

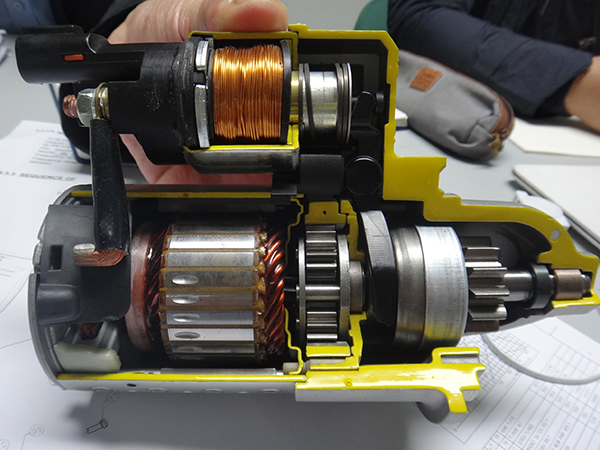

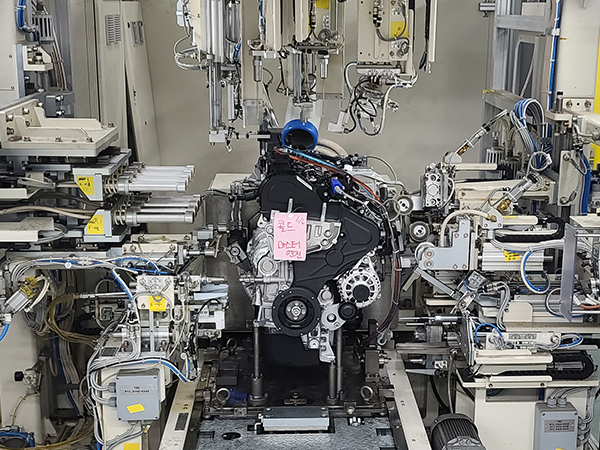

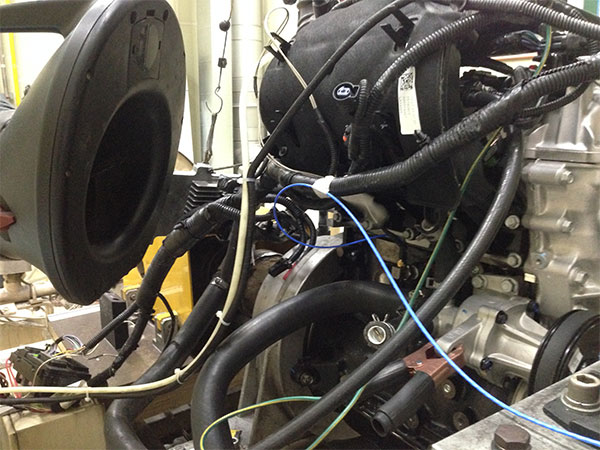

In General, The major characteristic of the engine's NVH data is input of impulse signal due to assembly failures. iNisys can enhance defect detection applying Peak Count and Delta Code for impact signals.

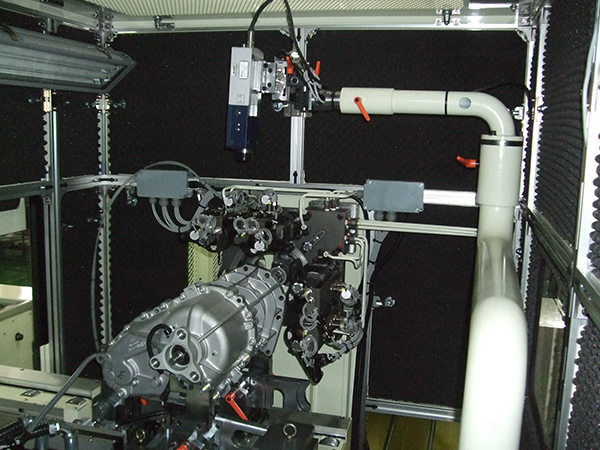

▲ Engine Cold Tester

▲ Hot Tester

▲ Hot Tester

▲ Engine Test Bench

▲ Vehicle Test

▲ Vehicle Test

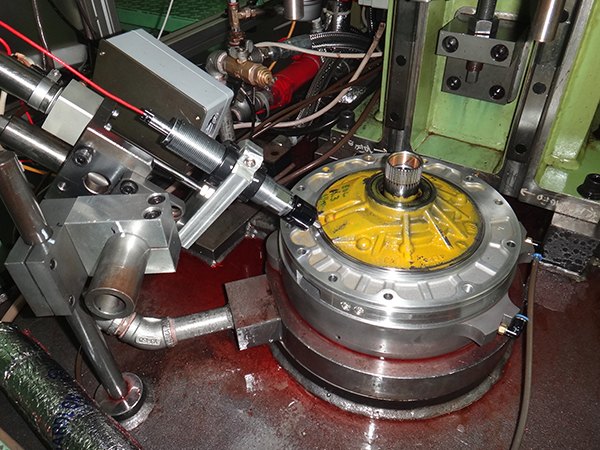

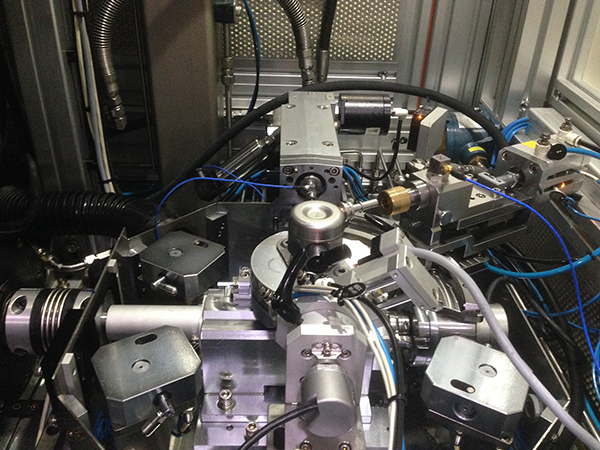

▲ Oil Pump

▲ DCT Gear Actuator

▲ DCT Clutch Actuator

▲ Diff side Gear Defect Detection

▲ SUB ASSY TF/DIFF Gear Nick Detect

▲ DCT GA Power Module

▲ GDI Pump

▲ BSM/BSA

▲ CVVD

▲ PCSV

▲ Audio Deck

▲ MDPS rattle tester

▲ MDPS operating noise tester

▲ HPCU Bolt Ingress Inspection