PIMA (Inline Modal Analyzer)

Inline Modal Analyzer

The in-line percussion acoustic measurement system is an application that can detect product defects based on the modal testing technique.

It is a product that can detect defects such as welding defects that occur during production through vibration measurement.

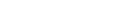

The percussion acoustic measurement system can be managed by setting a standard value according to each product characteristic, and the product can be evaluated for defects through real-time FRF measurement. An external control communication protocol and database related application are provided for inline inspection.

If an abnormal situation occurs during product evaluation, it notifies the person in charge by text message (SMS) or turns on the warning light and buzzer.

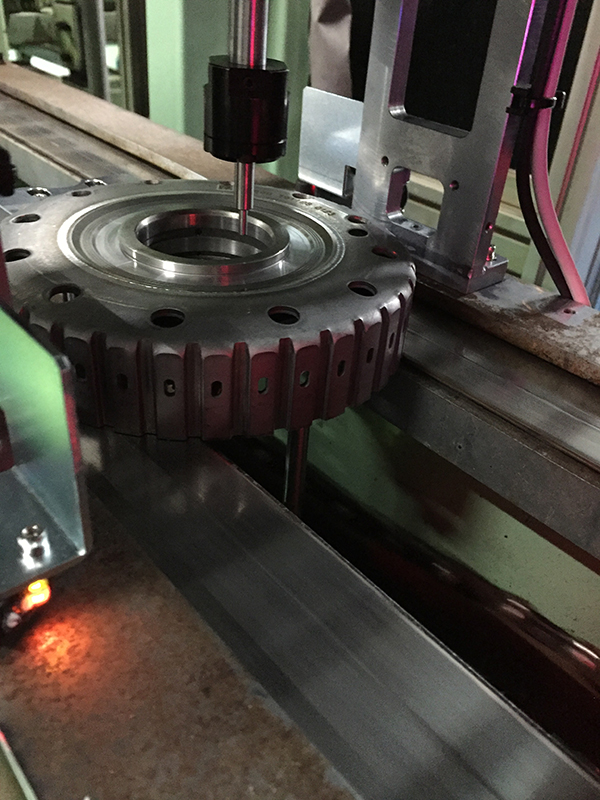

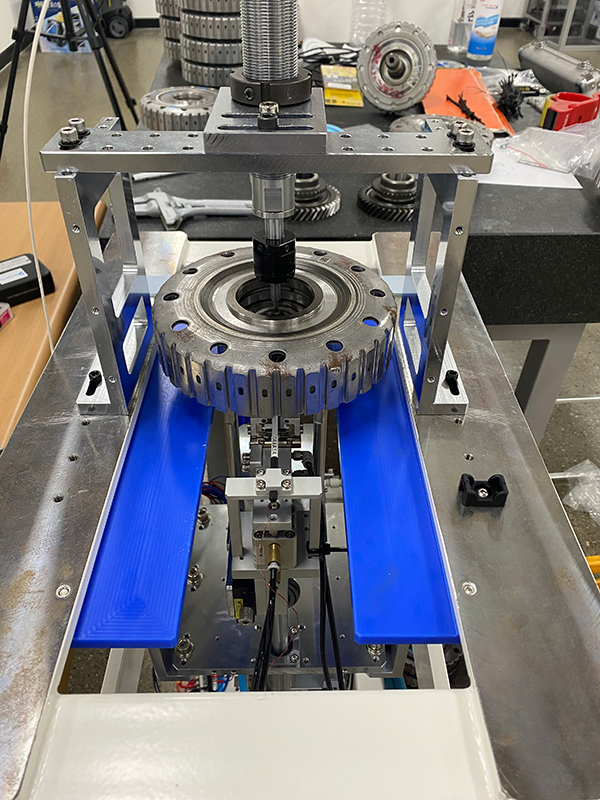

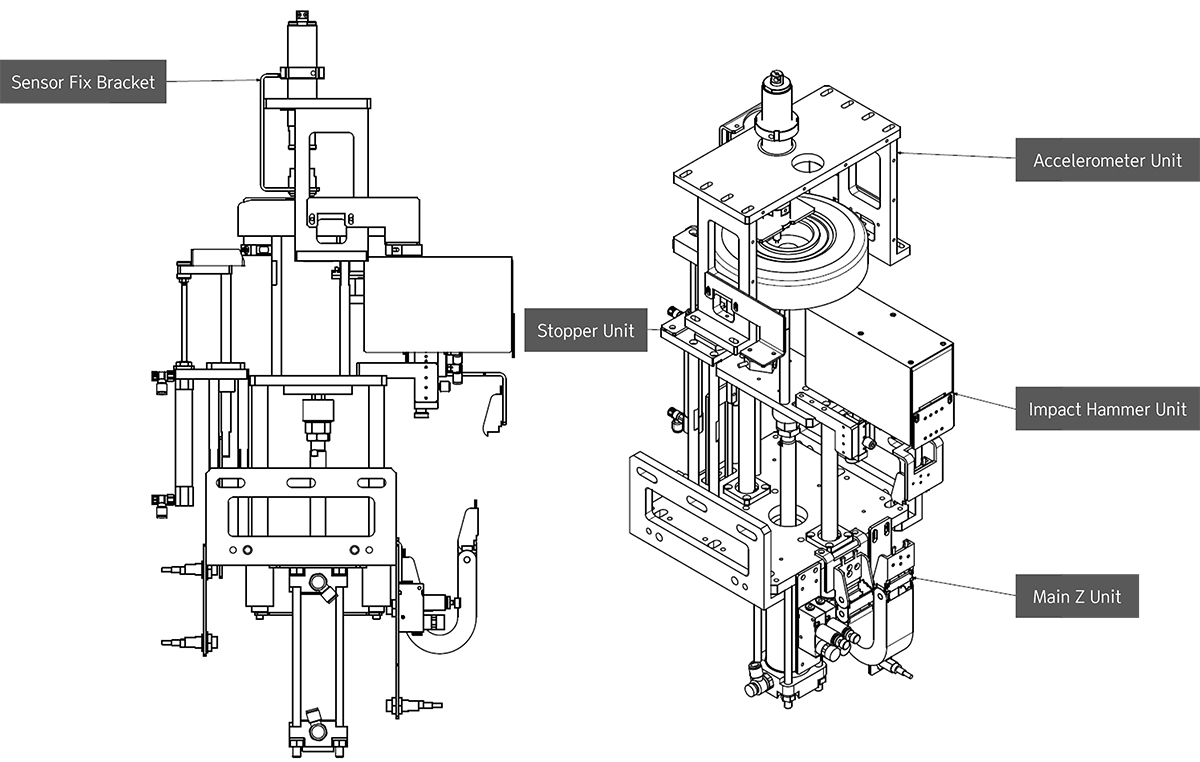

Hardware Configuration

Features

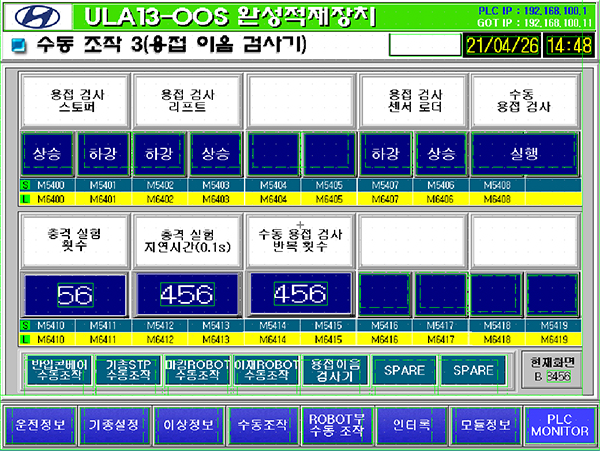

Noise Measurement PLC

- Weld Inspection Stopper and Lift Control

- inspection sensor loader

- Setting the number of impact tests

- Shock test delay time setting

- Set the number of iterations of welding inspection

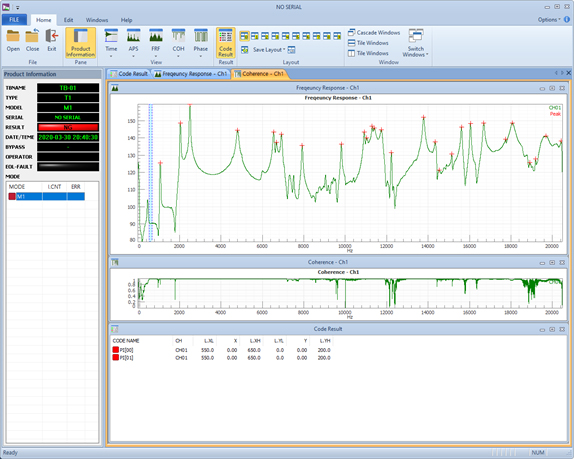

FRF or SIMO Test

- Used to check the resonant frequency of equipment and products

- APS/FRF/COH View

- Cross Spectrum

- Trigger Level Setup

- UFF58 Export

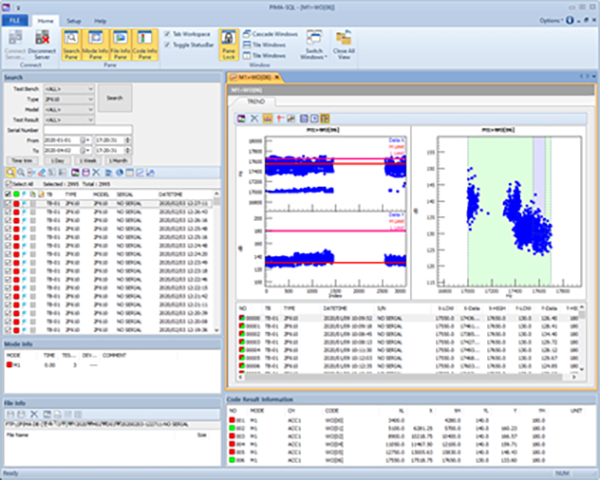

Data Search/View Program

- Spectrum Overlap

- Trend View

- Report Format setting and output

- Direct rate check function

Application