GDMS (Gear Dimension Measurement System Double Flank Tester)

Gear Dimension Measurement System Double Flank Tester

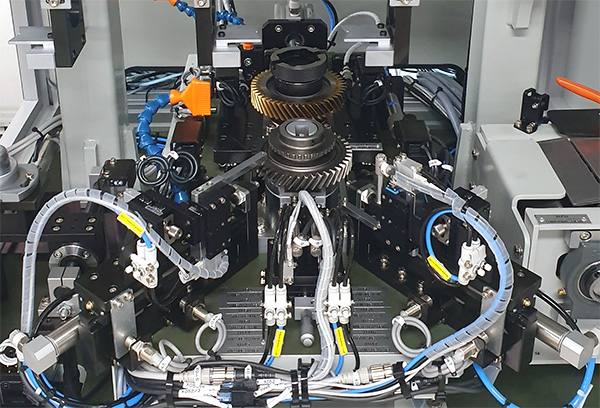

The gear dimension measuring system, a double flank tester, is a system that measures the dimensions of gears such as OBD, Runout, Inner Dia, Gear Nick, and Height.

The gear dimension measuring machine is divided into 1-Station or 2-Station method, and the assembly and processing conditions of the measuring device's mechanism are manufactured to a level of 5㎛ or less. Measurement of OBD, Inner Dia, Inner Dia Upper, Height, Runout, Upper Runout, Lower Runout, and Gear Nick is possible, and the repeatability satisfies 3㎛ or less based on 30 cycles.

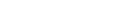

Hardware Specification

| Function | Specification |

|---|---|

| Servo Motor | MITSUMISHI 40W (10.8Nm) |

| Control Mode | CCW / CW / SPEED |

| Encoder | 3200 pulse / rev |

| Clamping Unit | MANDREL(Test Gear) / Manual(Master Gear) |

| Spindle | < Runout 5 um |

| Center Distance | Auto adjust |

| Size | 2800(W) x 1700(D) x 2100(H) mm |

| Etc. | Barcode Reading, Transfer Unit, NG Port |

Software Specification

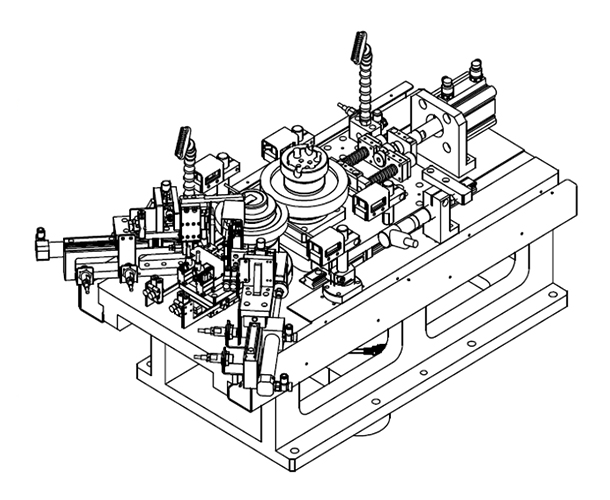

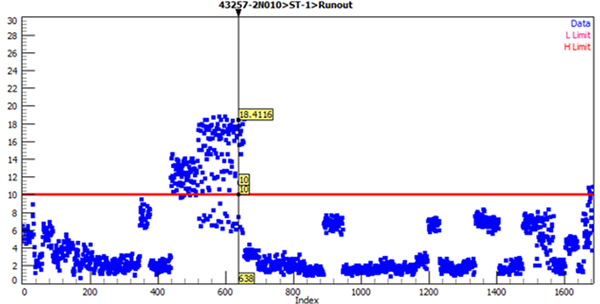

Runout Signal

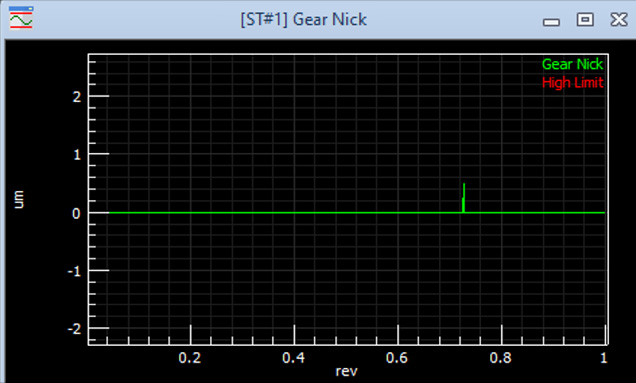

Gear Nick

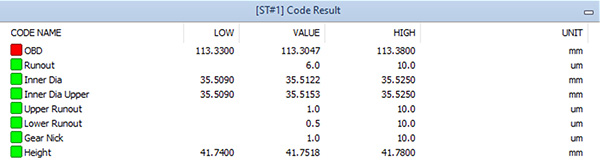

Measurement code result

| Function | Specification (Software) |

|---|---|

| Measurement | Runout, Upper Runout, Lower Runout / Gear Nick : um / OBD, Inner Dia, Inner Dia Upper, Height : mm |

| Measurement Station | Max. 2 Station support |

| Calibration | LVDT Setting using Setting Master Gear |

| Display Chart | OBD, Gear Nick, Runout, Upper Face, Inner Dia, Inner Dia Upper |

| Statistics | GDMS-SQL - Search / Statistics / Trend Analysis / Production Rate Analysis |

| ETC. | Camera VIEW & SAVE / Backlash Measurement |

- Storing product serial number using code reader

- Unload function for each type of defect in NG Buffer

- Indication of gear engraved position using a marking machine

- Data statistics processing function such as inquiry of production history of millions of products and data trend view by DB construction

- NICK data has no effect on runout measurements in OBD.

Application