VMS (Vibration Monitoring System)

Vibration Monitoring System

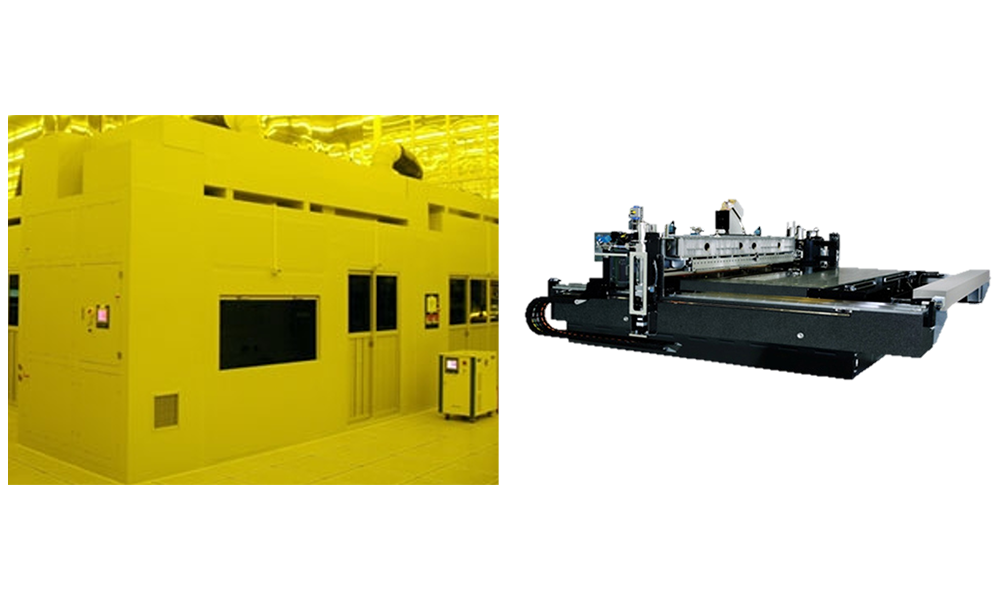

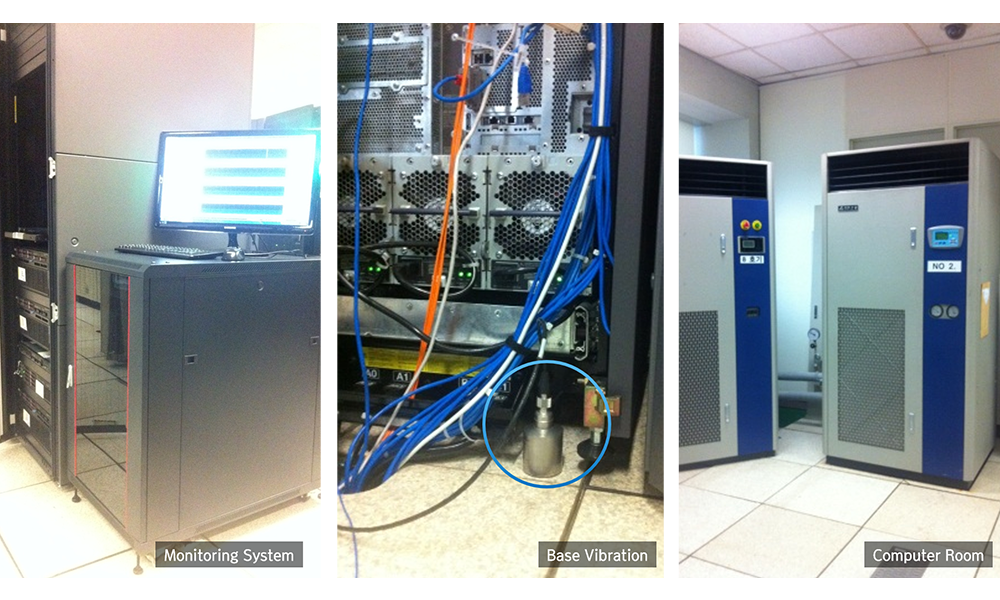

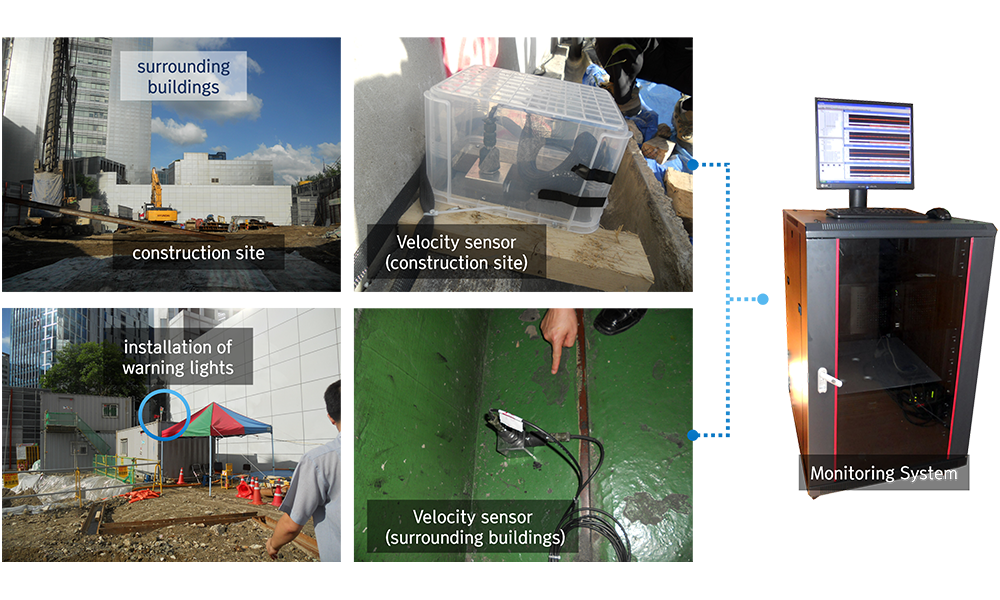

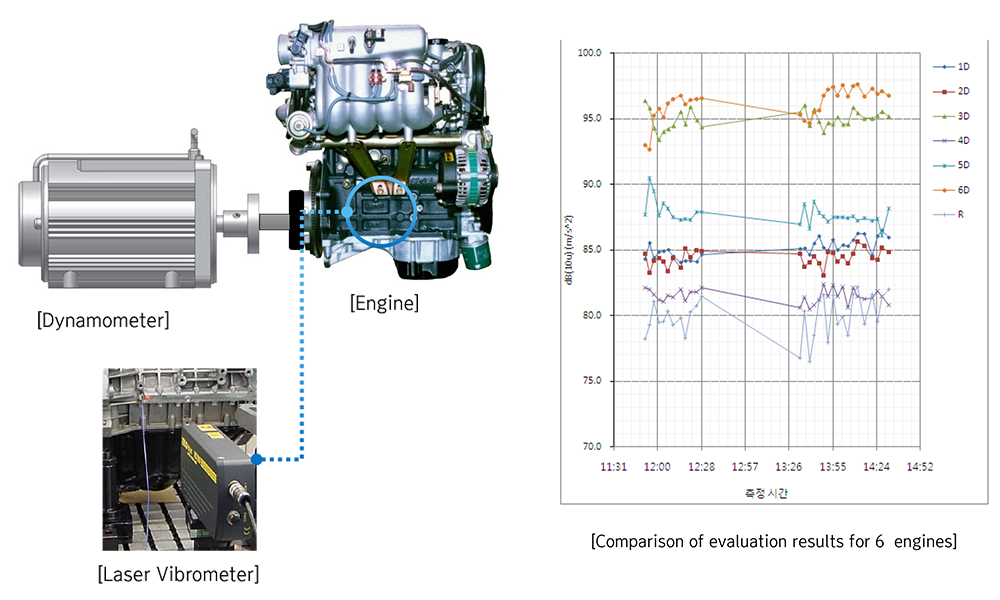

Vibration monitoring system is a product that can be applied to high-importance and fast-degrading equipment, products that require vibration measurement for enduring operating time, or vibration and noise measurement in living/environmental environments due to regulations.

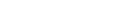

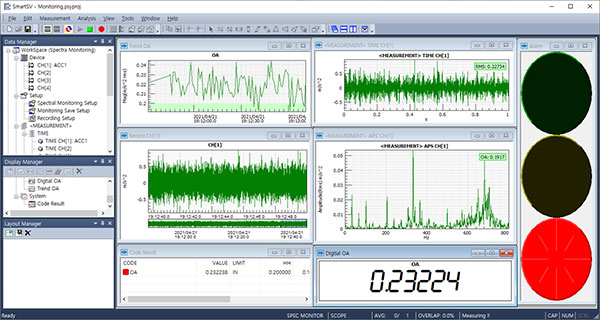

Monitoring is performed in regular sequence as measurement, analysis, judgment, and notification to users, and users can promptly recognize dangerous situations with warning lights and SMS notifications.

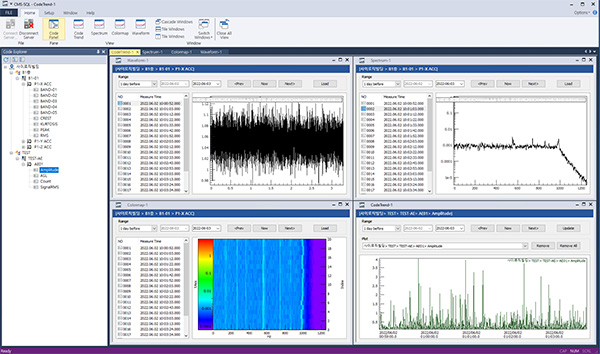

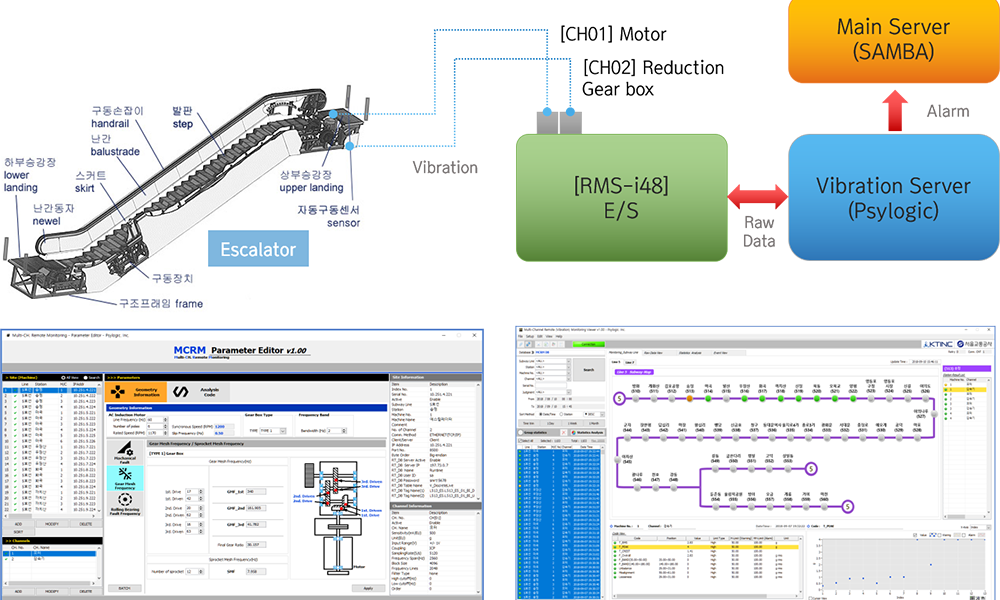

Monitoring systems often require multi-channel measurement, and VMS can monitor tens or hundreds of channels. Measurement data can be analyzed in time domain and frequency domain, and it has Octave analysis and Vibration Nomograph functions.

Hardware

1-axis accelerometer

3-axis accelerometer

4CH DSA

32CH DSA

OPC UA Interface Hardware

- Measure vibration(acceleration) and 3-axis inclination using MEMS

- Acquire data with 2 kHz sampling

- Outputs X, Y, Z-axis RMS and Peak Feature

- Periodic raw data OPC UA communication using server transmission

- Applicable to various programs using OPC UA communication

- Supports various measurement modes

- Monitoring Mode

- Triggering Mode

- Energy-Save Mode

| Item | Specification | |

|---|---|---|

| Measure setting | Sampling Rate | 2500, 2000Hz |

| Digital Filter | AC Filter (Digital) | - |

| Digital Filter | Lowpass, Highpass, Bandpass, BandStop | |

| Digital Filter 수 | 1EA per channel | |

| Pole 수 | 1~8 Pole | |

| Processing | FFT Window | Hanning |

| FFT BlockSize | 1024, 2048, 4096, 8192 | |

| Overlap(%) | 0, 25, 33.3, 50, 66.7, 75, 80, 90 | |

| Protocol | - | OPC UA |

| Analysis Code | Time Domain | Rms, Peak, Crest, Kurtosis |

| Frequency Domain | Overall, Band, Peak | |

| -. Coordination : Linear or dB | ||

| -. Peak Method : Rms, Peak, Pk-Pk | ||

| Average Method | Mean, Peak-Hold (Dual setting possible) | |

Software Feature

| item | Feature |

|---|---|

| data analysis |

· Time Domain Analysis (Rms, Peak, Crest, Kurtosis Etc) · Frequency Domain Analysis(FFT) · Octave Analysis · Vibration Nomograph (BBN Chart) |

| Judgment and storage |

· Defect area and location indication · When the standard is exceeded, recording vibration data at the time of occurrence are individually saved · It is possible to store and post-process analysis of recent measurement data. |

| Notifications and sending |

· Warning light notification function · SMS notification function · Data transmission to PLC or Main Server |

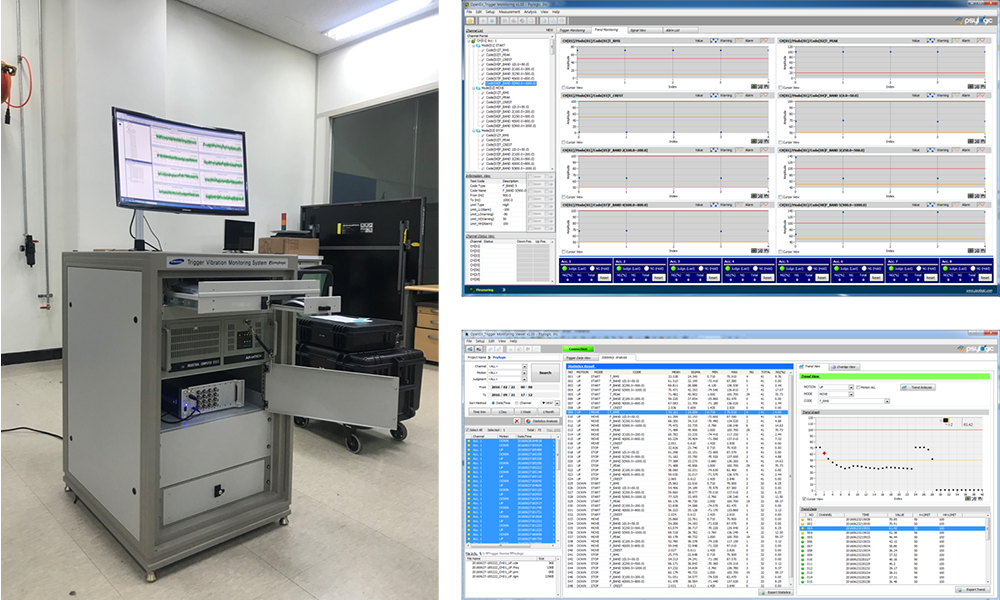

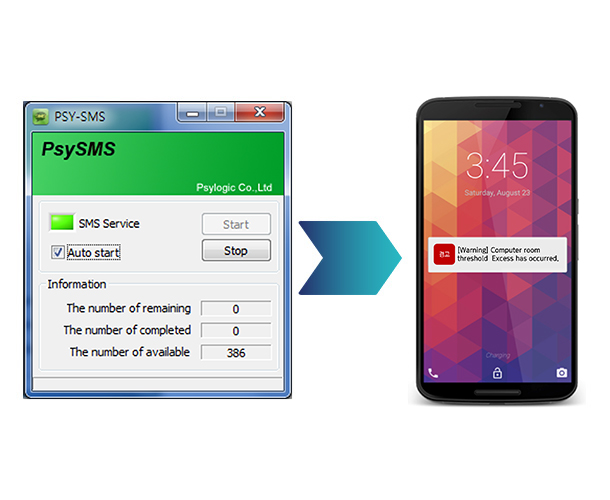

Trigger Monitoring

- Add/delete/manage devices

- AI/DI channel setting and group setting

- Trigger Manager: Interval, Edgy, etc. settings

- Machine and measurement mode settings

- Code View, Recording View, Spectrum View, Channel View

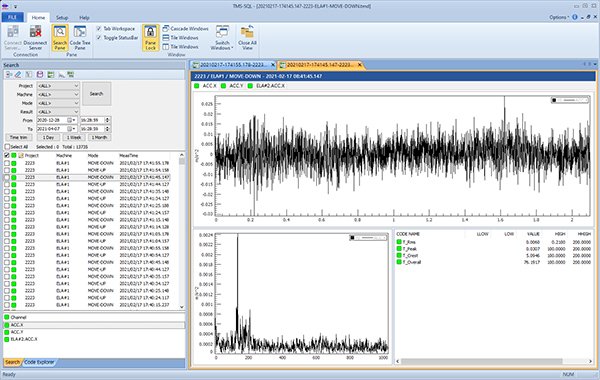

Data Search/View

- Trend View

- Spectrum Overlap

- Recoding Data Partial Frequency Analysis

- Data deletion and management

- User Management, Data Annotation, etc.

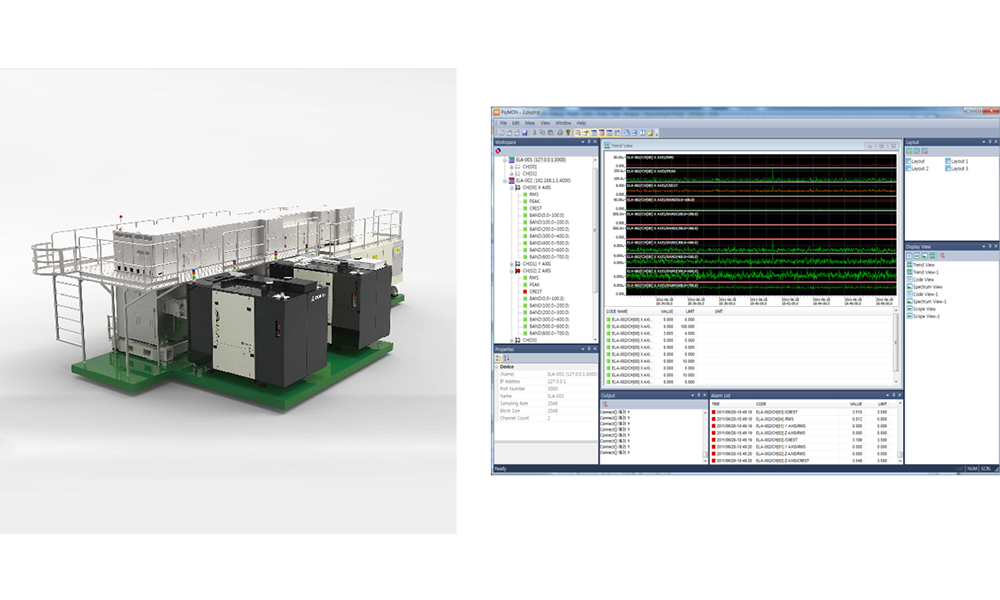

OPC UA Monitoring / Data Search

- 300 channel vibration data collection

- Capable of collecting wired and wireless communication data

- Support for wireless sensor module and monitoring body

- Time / Frequency Analysis

- Data Storage & Overlap Analysis

- OPC UA Interface