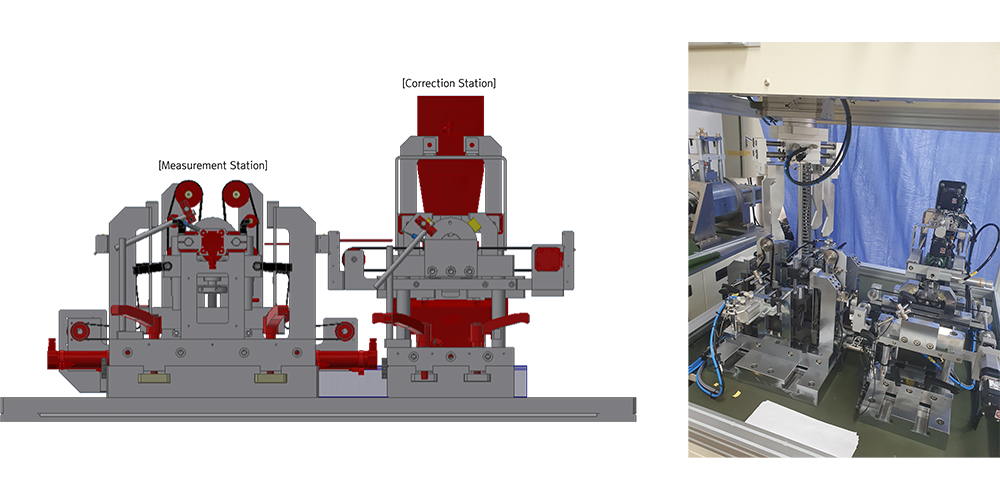

iBalance(Inline Balance System)

Inline Balancing

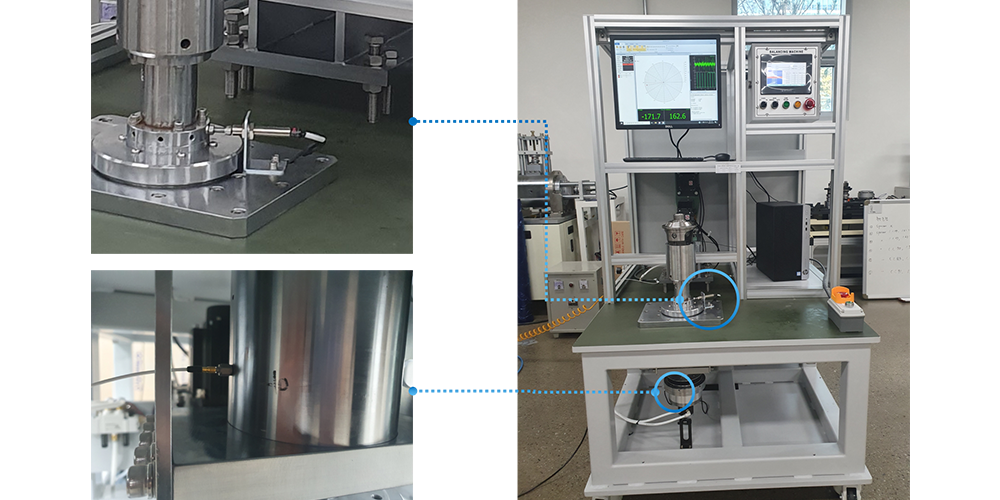

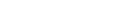

Imbalance causes lower the rotational drive efficiency, In order to enhance the balancing, such works of adding or removing weights at the opposite positions of imbalances based on the most accurate measure the mass and position of the unbalance of the rotating body.Balancing has been widely used in textiles, papermaking, turbines, machine elements area so far. Recently, as the commercialization of high-speed motors (EVs) has accelerated, the demand for balancing in motor assembly lines has increased, and the management level has also been dramatically raised.

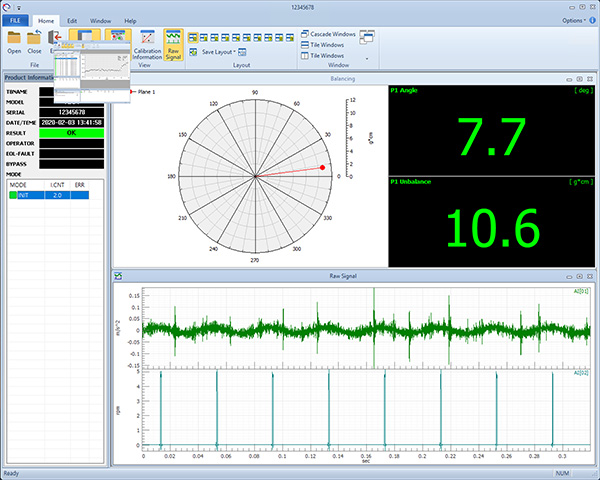

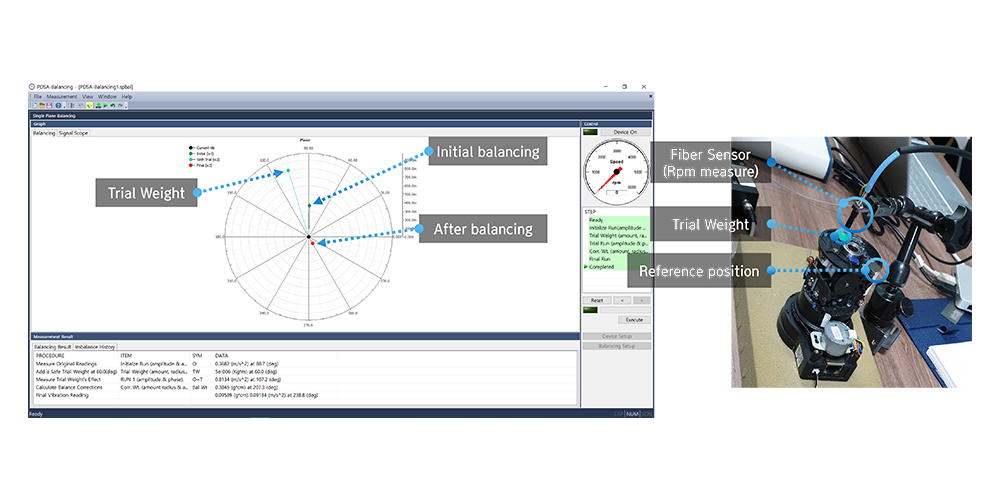

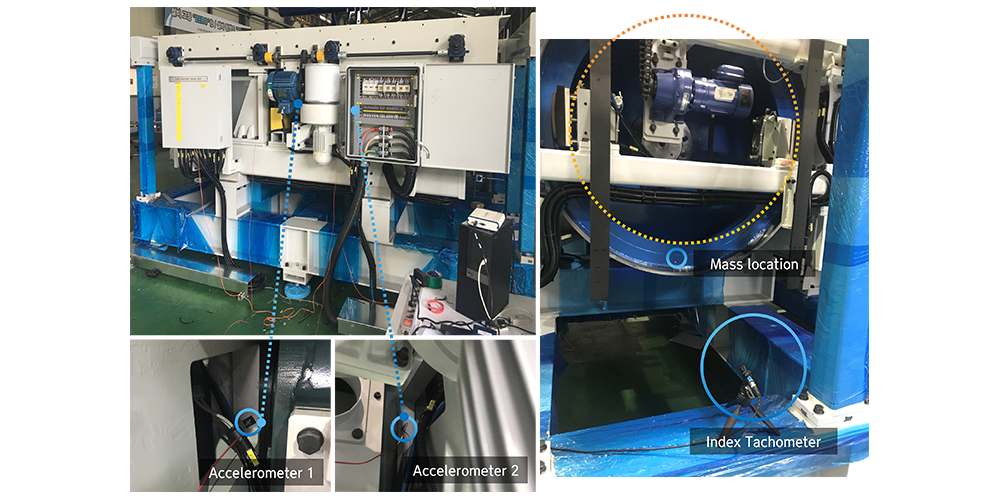

iBalance schematically designate the position of the unbalance of the rotating body to make it easy for workers on the production line to understand. In addition, it has a function to transmit the machine's travel distance for weight removal by inputting the machine's specifications. After machining, measurement/judgment whether proper balancing has been performed is carried out.

Feature

Balance Measurement Application

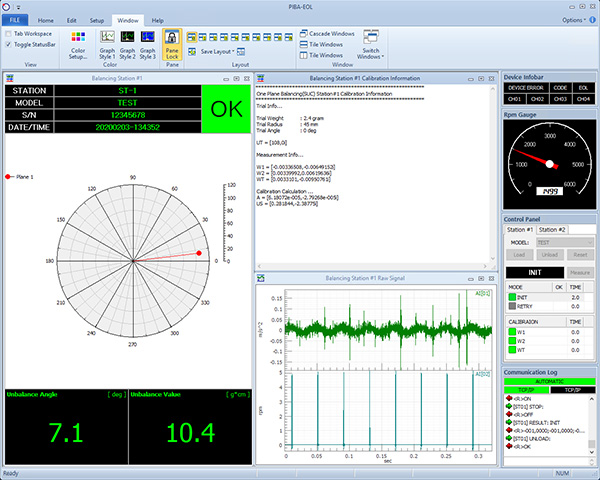

- Digital and polar display of unbalance amounts and angles

- Real-time vibration and index signal confirmation

- Automatic eccentricity correction function with one calibration when replacing the product jig

- Real-time Communication confirmation function

- Device defect check function

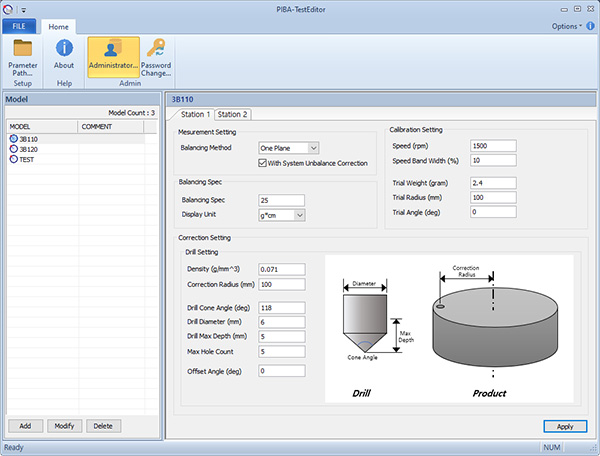

Parameter Management Program

- Model management (registration/removal)

- Machining location and machine specification management

- 1Plane or 2Plane balancing options

- Calibration Setting Management

- Balancing Spec Management

- Balancing unit management (g·cm, kg·mm, etc.)

Data Search/View Program

- Raw Data Viewer same as measurement screen

- Statistical processing (unbalance amount trend inquiry)

- Production Rate inquiry (defect rate inquiry)

- Raw data saving function

- Printer output function

- Measurement result HTML saving function